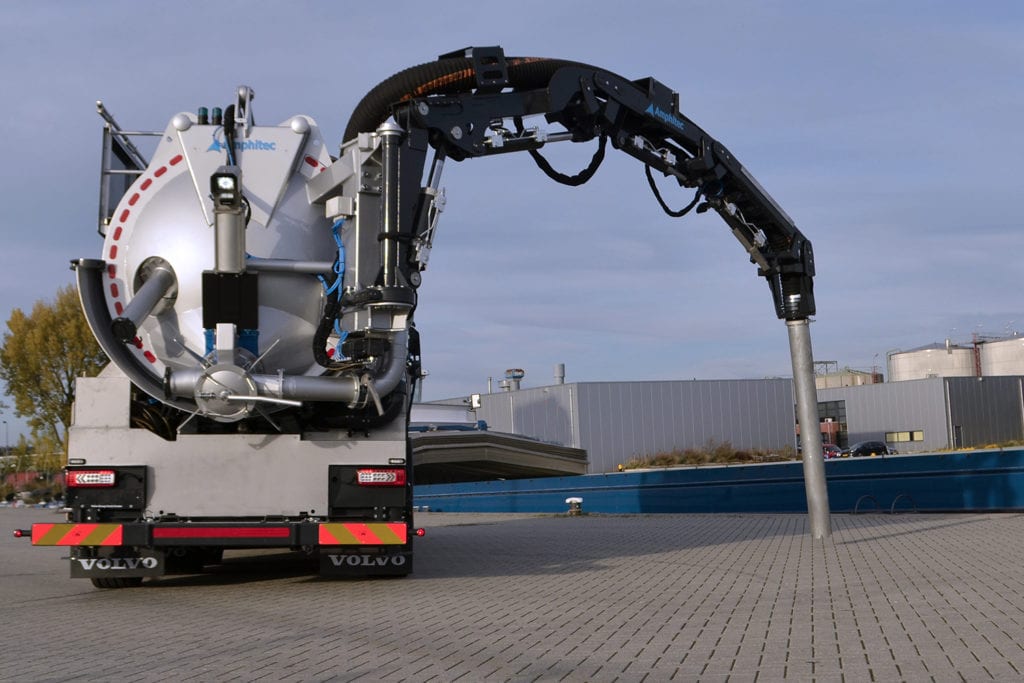

Amphitec Suction Excavator

General

The Amphitec Suction Excavator with its soil suction arm is specially designed for removing soil around cables and pipelines. The powerful vacuum/pressure technology ensures that soil, clay and sand are sucked up quickly and easily. All the advantages of the Amphitec Vortex are combined in the Suction Excavator; this makes the Amphitec Suction Excavator extremely suitable for a wide variety of purposes. The hydrostatic drive in combination with the soil suction arm means that this machine can be operated via remote control by a single person. The difference between the Amphitec vacuum concept and a traditional fan machine is, among other things, the high-capacity suction of liquids and working at depths.

Amphitec products are characterised by efficiency. The strong Roots Blower, which still performs very well at low speeds, and the optimal transfer of the gear box guarantee optimal fuel consumption. The machine offers the right balance, making your work go faster and safer.

vacuum technology vs ventilation technology

Features

Suction Excavation

- Safely clearing cables and pipelines

- Prevent damage to infrastructure

Suction of dry and liquid material

- Suction at 300m + from machine

- Sucking up materials at depths of 50m +

Blowing of dry products

- Blowing applications at 200m +

- Blowing height 75m + (high buildings, silo's, etc.)

Discharge & Tipping

- Save time discharging and cleaning the tank

- Leave the dumpsite properly cleaned - contribute to traffic safety

Transport

- Reduce maneuvering time and maneuvering damages

- Reduce discharge interruptions

The operating system

- Technology made simple again

- Safety as a result of ease of operation

The heart of the machine

- Fast filling & discharging of the tank

- Cover long vertical & horizontal hose distances

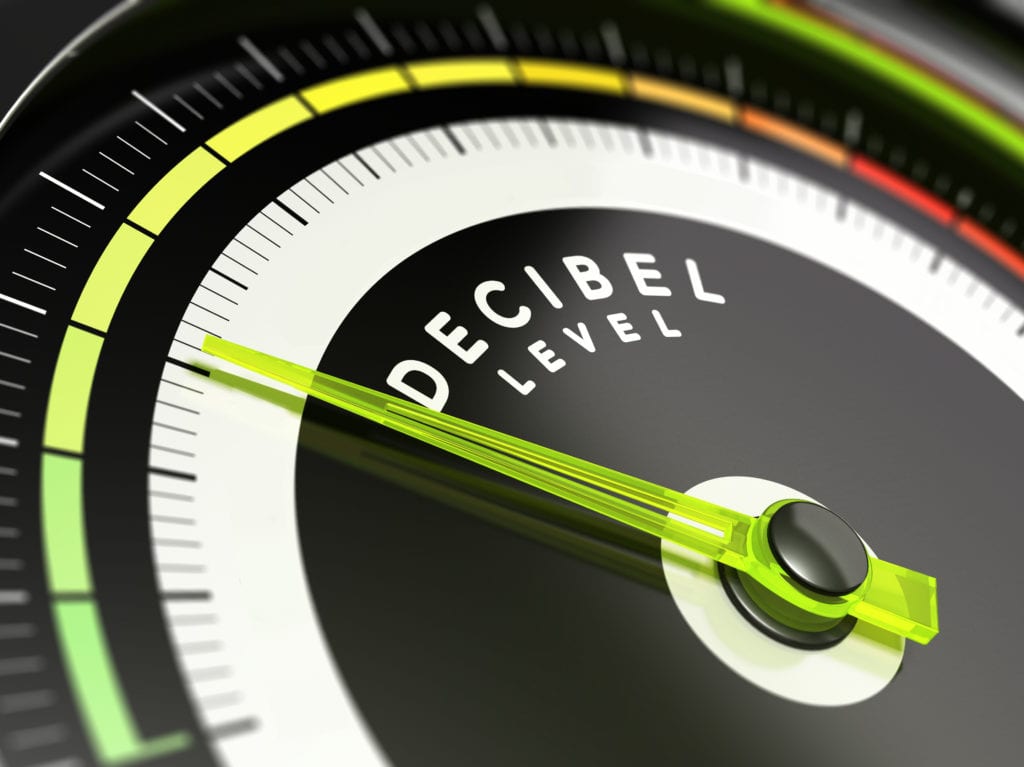

Noise reduction

- Minimal noise distribution (level below 80 dbA)

- Beneficial for human and environment

The drive

- Save on fuel cost

- Low engine emission

The filter chamber

- Filter hatch safely operated from outside product tank

- Quick cleaning due to smooth interior design

The main filter

- Save time, fast filter exchange

- Optimal particle separation

The filter cleaning system

- Suction performance remains high

- Sustainable for the environment - no dust emission

The safety filter

- Emission reduction protects human & environment

- Extension of pump lifetime

USER FRIENDLY

RELIABLE

EFFICIENT

INVOLVED

Main options

Amphitec® roots blower 11000

The Amphitec® roots blower 11000 model supplies airflow in both suction and blowing operation. This pump model is unique amongst all pump models as a result of a wide range of permissible pump speeds. Low speeds for blowing of materials and higher permissible pump speeds for vacuum jobs. The roots blower supplies a theoretical maximum airflow of 11000 m3/h, which results in fast pickup of partials during suction. The deep vacuum capability (96% vacuum) of the Amphitec® roots blower 11000 allows for optimal pneumatic transport of products through the hose. In

particular, this is required when sucking heavy product and sludges efficiently.

Blowing of products is done with a maximum pressure of 1,0 bar and an airflow of

2500 m3 p/h.

Amphitec® roots blower 18000

The Amphitec Vortex creates the highest airflow combined with deepest vacuum possible in the market making use of 2 Amphitec 9000 Roots Blowers and all the available truck engine power up to 700 hp, and so promotes maximum suction power and efficient material vacuuming with ease at DN 250mm hoses. Blowing is done with just one pump at low power. Fuel use is minimised because of the strong performance making a job short and easy. The suction excavation boom hose diameter is increased from 8″ to 10″.

Hi-Lift

Equipping the Amphitec® Vortex with a Hi-Lift system permits for discharge of tank content in a number of ways. The system allows for tank discharge into big-bags, containers, drums or other storage facilities. 2 hydraulic stamps are foreseen on the back of the installation in order to stabalize the backside of the machine during tipping of the tank. Discharge in containers with a maximum height of approx. 1.800 mm, is possible. The extra weight of the Amphitec® Vortex equipped with Hi-Lift is approx. 700kg.

Compressor

The installation of a robust 3m³ / 7 bar air compressor for the use of pneumatic tools. Two air connections are installed, one with clean air and one connection for air with oil mist. Included is 10m of air hose installed on a hose reel at the right rear side of the machine. Pneumatic tools not included.

Recodrive

With the hydrostatic drive system, the truck can be moved using the remote control system of the machine. The system consists of a gearbox installed on the truck drive shaft and a drive on the steering system on the front axle.

Moving the truck safely on short distances by the hydrostatic drive system enhances ergonomical working environment for the operator. Cabin entrees by the operator can be avoided for each small truck movement.

The truck is equipped with a security system. Objects at the front of the truck are detected and will cause a visual signal. Once objects are too close the truck will be stopped from moving.

Extra Hydraulical options

This option is only possible in combination with a suction boom. Extension of the hydraulic system and of the radio remote control of the suction boom, for the operation of following additional functions from the remote control:

– Open/close rear door locks

– Open/close rear door

– Tip/lower tank on front tipping cylinder

– Hi-Lift tip/lower (if Hi-Lift is installed)

HP pump

High pressure pump with a maximum waterflow of 50L/min and a maximum pressure of 120 bar.

The installed industrial high pressure pump is driven by a hydraulic PTO (PTO to be ordered with truck). A manually operated hose storage reel is foreseen at the rear side of the chassis and is equipped with 20 meter ½ “ high pressure hose. An air pressure connection is located next to the hose reel to be able to empty the hoses to prevent frost damage. The watertank is integrated in the front partition of the tank, content approx. 500L. This option is exclusively possible with a closed filter chamber configuration. The absorbed drive power of this HP pump is approx. 10kW. When desired other pumpconfigurations are possible.

Hose storage Hydraulic foldable

Hydraulic operated foldable hose storage comparments on both side of the machine for the storage of hoses and pipes. Per storage compartment hoses can be stored on 4 levels.

Hammers

A set of 2 heavy pneumatic hammers mounted underneath the tank. 1 hammer mounted under the filter chamber and 1 in the middle of the product tank. The hammers are type FKL100. These hammers are suitable for the removal of adhesive material crusts on the tank wall and as bridge breaker of materials in the tank.

Discharge compressor

Discharge compressor, 165 m3/h, max. 2 bar.

The installed industrial compressor is driven by the hydraulic drive from the PTO mounted on the trucks engine. The high permissible maximum pressure of 2 bar allows the operator to even discharge high viscosity products out of the product tank without any problems. Including overpressure safety, set at 2 bar working pressure.

– Max. overpressure 2 bar

– Max. air volume approx. 165 m³/hr

– Max. required drive power approx. 8 kW

DN300 for bigbags

DN300 slide valve installed on the back door of the machine, for the discharge of free flowing material in big-bags and containers.

ATEX

ATEX provisions and certificate in 1D, 2D and 3D is possible. Equipment is intended for use of suction from areas in which explosive atmospheres caused by air/dust mixtures are likely to occur. The means of protection relating to equipment in the various categories ensure the requisite level of protection, even in the event of frequently occurring disturbances or equipment faults which normally have to be taken into account.

ADR

The machine is suitable for the suction and transport of ADR material of classes S4AH and L4AH (3 4.1, 5.1, 6.1, 6.2, 8 en 9). All required ADR provisions are applied.

Open filter chamber

Open configuration of the filter chamber which is suitable for suction of dry material only. The standard filter hatch is withdrawn in order to optimize loading volume and to facilitate easy cleaning of the filter chamber. The suction inlet is located on the left side of the machine and blows in vacuumed materials towards the tank rear side. Level swiches are excluded.

SIR

SIR Package – Industrial safety provisions installed on the machine according SIR guidelines. (SIR is the Dutch industrial safety authorization). The package is composed by a continues earthing monitor including green lamp, 2 hand operation for opening rear door + locks and a fall safety for the tank rear door. Inspection and certificate are included in the delivery.

Stainless steel toolboxes

Installation of an additional stainless steel toolboxes is possible in various dimensions on a location of your choice provided that sufficient space is present.

3, 4, or 5 chassis

The Amphitec Vortex body is standard installed on a 4 axle chassis. When desired a 3 or 5 axle chassis and body is possible. The de- or increased tank/body length allows for manufacturing a more manoeuvrable machine or a machine with a very high payload. The product tank volume will be 12m³, 15m³ or 19m³.